Print materials have measurable characteristics that you need to consider when selecting or designing forms for your particular application.

Basis weight is a term used to describe the weight in pounds of 500 sheets of paper (one ream). However, the standard paper size determines the weight, which may not be the purchased size. Therefore, the basis weights are not always easily comparable. An example would be the standard size of 20-lb bond paper, which is 17 x 22 inches, and one ream that weighs 20 pounds. If the paper was cut, creating four reams of 8.5 x 11-inch paper, then each ream would be labeled 20-lb bond paper but would only weigh five pounds.

If the same paper weighed 24 pounds, it would be called 24-lb bond. The 24-lb bond paper is thicker, heavier, and more dense than the 20-lb bond. Thicker paper means that less paper can be placed in a tray. Paper that is heavier and more dense may cause paper jams or feed reliability problems in some printers. To verify that the paper basis weight being used is acceptable, see the supported paper weights table in Printer-specific paper support .

Not all basis weights are related to the same standard sheet size. For example, a 70-lb material can be lighter than 40-lb material if it is based on larger base size paper. The metric measurement of grams per square meter (g/m 2 ) is a more consistent way to compare weights and has been standardized by the International Organization for Standardization (ISO).

Your printer can accept a wide range of stock weights, but materials either too light or too heavy can cause printing problems. Heavy and thicker materials may not heat quickly enough in the fuser, resulting in poor print quality. They may also feed less reliably or skew due to their weight or rigidity. Conversely, lighter materials can wrinkle and jam in the printer due to low beam strength (stiffness).

Use the following table to compare the weights of various types of media.

|

Metric equivalent (g/m 2 ) |

Basis weight (lb/ream) |

|||||

|---|---|---|---|---|---|---|

|

Bond 431.8 x 558.8 mm (17 x 22 in.) |

Offset 635 x 965.2 mm (25 x 38 in.) |

Cover 508 x 660.4 mm (20 x 26 in.) |

Printing Bristol 571.5 x 889 mm (22.5 x 35 in.) |

Index Bristol 647.7 x 774.7 mm (25.5 x 30.5 in.) |

Tag 609.6 x 914.4 mm (24 x 36 in.) |

|

|

Card stock weights may vary ± 5%. |

||||||

|

60 |

16 |

40 |

18 |

23 |

33 |

37 |

|

75 |

20 |

51 |

28 |

34 |

42 |

46 |

|

80 |

21 |

51 |

30 |

36 |

44 |

49 |

|

90 |

24 |

61 |

33 |

41 |

50 |

55 |

|

100 |

27 |

68 |

37 |

46 |

55 |

62 |

|

110 |

29 |

74 |

41 |

50 |

61 |

68 |

|

120 |

32 |

81 |

44 |

55 |

66 |

74 |

|

145 |

39 |

98 |

54 |

66 |

80 |

89 |

|

160 |

43 |

108 |

59 |

73 |

88 |

98 |

|

175 |

47 |

118 |

65 |

80 |

97 |

108 |

|

200 |

53 |

135 |

74 |

91 |

111 |

123 |

|

215 |

57 |

145 |

80 |

98 |

119 |

132 |

|

255 |

68 |

172 |

94 |

116 |

141 |

157 |

|

260 |

69 |

176 |

96 |

119 |

144 |

160 |

|

300 |

80 |

203 |

111 |

137 |

166 |

184 |

Depending on the orientation of the stock as it feeds through the printer, you may need to request that heavier materials be cut grain short or grain long to provide flexibility in paper path turns.

For more information about the weights your printer supports, see the individual printer specifications in this document.

All printers have print material dimension limitations. For more information, see the printer documentation. You can sometimes redesign your printed output to overcome these limitations. For example, if your document is shorter than the minimum length supported by the printer, then you can place two documents on a single sheet.

Lexmark printers meet or exceed all industry emission regulations and standards. Continuous printing on some paper types or other media may create fumes that are not a problem with occasional printing. Make sure that your printer is located in a well-ventilated area.

Temperature and humidity can have a major impact on printing. Even small changes (such as from day to night) can greatly affect feed reliability when the print material is just within the range of acceptability.

We recommend that you condition stock while it is still in the original wrapper. Store the stock in the same environment as the printer for 24 to 48 hours before printing to let the stock stabilize at the new conditions. You may need to extend this time by several days when the storage or transportation environment is very different from the printer environment. Thick stock also requires a longer conditioning period because of the mass of the material.

If you remove the wrapper from the stock before you are ready to load it in the printer, the stock develops uneven moisture content causing the stock to curl. Before loading, we recommend the curl not to exceed 3 mm (0.125 in.). Lighter materials, such as paper labels and some integrated forms, are more likely to have printing problems if curl is present.

Most label manufacturers recommend printing in a temperature from 18–24°C (65–75°F) with relative humidity of 40–60 percent. Lexmark printers are designed to operate in a temperature range of 15.5–32°C (60 to 90°F) with relative humidity of 8 to 80 percent. Printing in an environment outside these recommendations may cause jams, feeding problems, reduced print quality, and predispensing (peeling) labels.

Preprinted stock introduces semiliquid and volatile components to the high temperatures and pressure used in the laser printing process. Preprinted inks and colorations withstand a fuser temperature up to 225°C (437°F) and a pressure up to 25 psi without contaminating the printer or creating hazardous fumes.

We do not recommend thermography ink. Thermography inks have a waxy feel, and the printed image appears raised above the surface of the print material. These inks can melt and damage the fuser assembly.

Preprinted inks must also be abrasion-resistant to reduce ink dust and ink contamination in the printer. If you are printing over a preprinted area, the ink must be receptive to toner to ensure adequate fusing.

All preprinted inks must be thoroughly dry before using printed materials. However, we do not recommend using offset powders or other foreign materials to speed drying. To determine whether the ink is compatible with printers that heat the ink to 225°C (437°F), see your ink converter, manufacturer, or vendor.

If a perforation exists, the perforation line should stop 1.6 mm (0.06 in.) from each edge of the form. Doing so avoids separating the form in the printer path, resulting in a jam. The location of the perforation affects initial pick strength. Perforations closer to the edge may increase the number of jams. For pressure-sensitive materials such as labels, minimize the number of perforations that go through the backing material or liner.

Perforations should be ironed so the print material lies flat, reducing nesting of forms. Edges should be smooth and clean with no roll-over. Laser-perfs (also known as micro-perfs or data-perfs ) provide greater stability and are preferred. These smaller perforations do not normally nest or create excessive paper dust and debris. Make sure that the paper chaff and dust created during the conversion process are removed before packaging.

If perforations tent , or crease at the perforation line, the perfs may break, causing a paper jam. Tenting may increase skew, cause double-sheet feeding, or smear the toner on the print material before fusing, resulting in poor print quality. To reduce tenting, use micro-perfs. If the print material is lightly snapped as it moves through the printer, the perforations should hold without breaking.

Die-cutting is used to create shapes in a label or a card stock design. When designing labels, round all corners to prevent delamination of the labels, and avoid cuts through the liner (anvil cuts). Back splits and pop-out windows are also not recommended.

If perforations or die-cuts are part of the design of the print material, ties are recommended. These small uncut areas (approximately 1.6 mm or 0.06 in.) help stabilize the form and prevent tearing at perforations and die-cuts during printing.

For areas with die-cuts or perforations that intersect or create a small end product, ties on the corners of the design provide added stability. Ties may be located anywhere along perforations or die-cuts. For pressure-sensitive products, ties help prevent the labels from peeling off the liner while in the printer. Ties cannot be used to compensate for inadequate release strength of the adhesive in label designs.

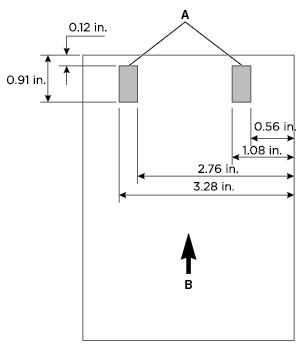

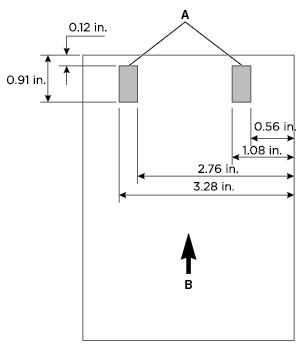

Some printers have a pick roller assembly that feeds paper more reliably than the corner buckler system used by earlier printer models. The assembly has two rollers that touch the media paper. Avoid placing deep perforations in these areas since the paper may nest, causing multiple sheets to feed. Perforations that could cause nesting and tenting should fall outside the pick roller area on the leading edge of the paper. This is different from the 0.50-inch space we recommend leaving at the top of the form for printers with a corner buckler system. Use micro-perfs to avoid nesting problems.

Make sure that perforations fall outside the 0.12–0.91-inch area on the leading edge of the media.

|

A |

Pick roller location |

|

B |

Feed direction |

Avoid debossing and embossing materials. The use of these materials may lead to nesting and double-sheet feeds, and the fusing process significantly reduces the height of the raised image. Printing too close to embossments results in poor print quality and poor fuse grade.

We do not recommend using metallics in forms, whether in inks or other materials, due to their conductivity and their ability to bleed charge. This property can interfere with toner transfer and cause poor print quality.

When designing forms, include a non-print area of 8.38 mm (0.33 in.) at the top and bottom of the form and 6.35 mm (0.25 in.) on both sides of the form.

In general, portrait orientation is the preferred layout, especially if you are printing bar codes. Choosing landscape orientation may cause the variations in paper path speed to produce spacing variations when printing bar codes.