Nhãn

Nhãn

hoặc vật liệu nhạy cảm với áp suất là vật liệu nhiều lớp có sự kết hợp của các tấm mặt (vật liệu có thể in được), keo dính và lớp lót bảo vệ có thể tháo rời (lớp lót). Các lớp này có thể tạo ra vật liệu dày khó xử lý.

Nhãn là một trong những vật liệu in khó nhất đối với bất kỳ máy in nào để nạp và in một cách đáng tin cậy. Các yếu tố, chẳng hạn như nhiệt độ, áp suất và đường dẫn giấy, có thể khiến việc in trên nhãn trở nên khá khó khăn. Ví dụ: nhiệt độ gần 225°C (437°F) và áp suất tới 25 psi có thể cần thiết cho quá trình thấm mực. Nhiệt độ thay đổi giữa các máy in. Kiểm tra phần dành cho máy in cụ thể của bạn. Vật liệu in nhãn dày có thể hấp thụ nhiệt, ảnh hưởng đến độ bám dính của mực và chất lượng bản in, gây ra hiện tượng tách lớp.

Lưu ý:

Đảm bảo bạn sử dụng nhãn được thiết kế riêng cho máy in laser để tránh nhãn bị bong ra hoặc tách lớp.

Label guidelines

-

Set the paper size, type, texture, and weight in the Paper menu to match the labels loaded in the tray.

-

Print samples on labels before buying large quantities.

-

Use labels designed specifically for laser printers.

-

Do not use labels with slick backing material.

-

Do not use labels with exposed adhesive.

-

Use full label sheets. Partial sheets may cause labels to peel off during printing, resulting in a jam. Partial sheets also contaminate the printer and the cartridge with adhesive, and could void the printer and toner cartridge warranties.

-

Flex, fan, and align the label edges before loading.

-

Use only label sheets that have no gaps between the labels.

-

Do not print a large number of labels continuously.

-

Do not use labels that have coating or sizing applied to make the labels liquid-resistant.

-

Run labels only once through the printer as this may contaminate the printer.

-

Load label sheets with the label end first.

-

Use grain long paper instead of grain short paper, which tends to curl easily.

Review label designs with a converter or a vendor who has extensive knowledge about labels and laser printers to ensure that you are using the proper type of labels.

For more information about label support for your printer, see

Hỗ trợ giấy dành riêng cho máy in

.

Label components

Labels are composed of three basic parts: the liner, the adhesive, and the face sheet. Labels may also have topcoats that affect printing. To prevent labels from peeling off, follow the recommended label design guidelines. Peeled off labels could cause jams. The label or adhesive could also melt when the sheet is jammed in the fuser. Choosing appropriate materials for each of these label components helps ensure reliable printing.

Liners

The

liner

, also known as the carrier or backing, is the material onto which the label is attached. The liner carries the label through the printer and directly affects feed reliability. Liner weights and construction vary based on the printable face stock used. For more information, see

Face sheet (printable stock)

.

Tissue-backed, plain bond, or bond-like, porous, lay-flat liners are preferred. Liners constructed for use with high-speed laser printers (50 pages per minute or more) may not produce acceptable results.

A liner should bend easily and go back to its original flat state when released. Forms that remain bent may cause paper jams or damage to the edge of the sheet. This bent affects earlier printer models using a corner buckler rather than a pick roller assembly to separate the sheets.

Some liner materials used in pressure-sensitive constructions are called

label papers

. Label papers are either machine finish (MF) or English finish (EF) papers that are calendered, supercalendered, or coated on one side. An MF has varying degrees of surface smoothness. The number of times the paper passes through the rollers (wet or dry) during manufacturing determines the surface smoothness. An EF is uncoated and low gloss in appearance. Label papers may also be used as the face sheet for pressure-sensitive paper products, such as the materials used in dual web forms construction.

Supercalendering

produces high gloss surfaces that may be slick. Some supercalendered liners are difficult for printers to pick and feed reliably. We do not recommend using supercalendered liners designed for high-speed laser printers (50 or more pages per minute).

Some pressure-sensitive constructions use kraft liners or bleached ones. Kraft liners are made from sulfate pulp and are MF or machine glazed (MG). Most MG papers have a high gloss appearance. High gloss, glazed surfaces may increase skew and are more difficult for the printer feed mechanism to handle reliably. Some kraft liners may produce acceptable results; however, we strongly recommend extensive testing of pressure-sensitive constructions using kraft liners.

Tissue-backed or plain bond liners reduce toner contamination inside the printer and improve feed performance. Slick, non-porous liners are harder to feed and increase toner buildup in the fuser and on the backup roll. Rough backings can increase paper path friction, which can cause skew and paper jams. The face material of the liner needs to have a melt temperature that can also withstand the fuser temperatures of nearly 225°C (437°F). A stripped area of a maximum of 3 mm (0.12 in.) can expose the face material to these temperatures and could cause melting or contamination in the fuser.

Excessive paper dust or chaff associated with the liner may affect print quality. If a liner produces excessive paper dust or chaff during conversion, then the debris may be packaged with the material and end up in the printer. These properties as they feed through the printer may also affect print quality. For more information about liners, see your label supplier.

Adhesives

There are three basic types of label adhesives: removable, permanent, and semipermanent (cold temp). All types, with proper design, can be used with your printer. Acrylic-based adhesives are generally preferred for cut-sheet label printers.

The major adhesive-related printing problem is printer and cartridge contamination. The adhesives are semiliquid and may contain volatile components. If the sheet jams in the fuser, the adhesive can melt, contaminating parts of the printer or releasing fumes. To avoid exposing adhesive to the paper path guides, drive rollers, charge roller, photoconductor drum, transfer roller, and detack fingers, use full label sheets.

Zone coating

means placing the adhesive only where needed. Paper labels and integrated forms typically use zone coating. In addition, a non-adhesive border of 1 mm (0.04 in.) around the outside edge of the label sheet generates good results. For more information about designing labels for your printer, see your adhesive manufacturer or label supplier.

A

stripped edge matrix

along the outer border of the stock, combined with adhesive that does not ooze, helps prevent adhesive contamination. This design requires a stiffer backing material to prevent damage when the sheet is aligned on the reference edge. Generally, vinyl and polyester labels are well-suited for this design. Paper and dual web designs may require testing to determine which backing produces good results.

Make sure that the release strength is adequate so labels stay attached to the liner and do not peel off in the printer. Adhesives should withstand pressures up to 25 psi and fuser temperatures of 225°C (437°F) without delaminating, creating hazardous fumes, or oozing around edges of labels, perforations, or die-cuts. Shear strength should be strong enough to prevent adhesive stringers. For more information, contact your label supplier.

Face sheet (printable stock)

Paper, vinyl, and polyester are the most common materials used for printable stock. Printable stock must withstand temperature up to 225°C (437°F) and pressures up to 25 psi. For more information, see your label supplier.

Carefully test the printable stock to make sure that it functions satisfactorily with your printer.

Topcoats

Topcoats for non-paper labels may be either water-based or solvent-based. Avoid topcoats containing chemicals that emit hazardous fumes when heated or exposed to pressure. Topcoats affect the print quality, feed reliability, and adhesion of toner to the face sheet. Topcoats should withstand temperatures up to 225°C (437°F) and pressures up to 25 psi for 100 milliseconds to prevent fuser damage.

Water-based topcoats tend to be more conductive than solvent-based topcoats and are more difficult to fuse. With some water-based topcoats and heavy liners, the fuse grade may fall below acceptable levels. Solvent-based topcoats tend to be lower in conductivity than water-based topcoats. With some solvent-based topcoats, fuse grade is within acceptable levels when heavier liners are used.

Print quality may degrade when using topcoats on labels with heavier liners. Using a lighter liner may reduce the appearance of splatter. Carefully test the labels to make sure the topcoat functions satisfactorily with your printer.

Label characteristics

The materials used to construct labels have a wide range of properties that can affect printing. Volatile components are in the label materials and in the adhesive itself. We recommend that volatile emissions from the label, up to 160°C (320°F), should be a minimal amount. The volatile components, which have low boiling point, produce emissions when heated in the fuser and could emit vapors that can damage the printer.

Preprinted inks can also cause printer contamination, and may be present on one or both sides of the label sheet.

Before purchasing large quantities of labels, make sure that you extensively test the labels with your printer.

Labels with a stripped edge matrix do not have the area around the outer edge of the cut sheet. Labels with a total strip matrix do not have the die-cut stock around and between the labels. This property makes it easy to peel the labels from the backing.

Butt cut labels are cut flush to one another, with no extra area between them. Avoid using butt cut labels without a stripped edge matrix.

Die-cut labels are cut with a non-print area between each label. For best results, do not print within 2.3 mm (0.09 in.) of the edge of the label, of the perforations, or of the die-cuts of the label.

If you are using a butt cut or die-cut label, then make sure that adhesive contamination does not occur. Labels use varying levels and types of adhesive, and various liner materials and face stock papers. Adhesive can ooze from all label stocks. Make sure that die-cuts are free of adhesive stringers. To prevent adhesive contaminations, use zone coating or pattern adhesive with a non-adhesive border of about 1 mm (0.04 in.) or larger.

If zone coating is not used, then we recommend a stripped edge matrix. The stripped edge matrix varies with the type of face stock, liner, and adhesive materials. The following table shows the guidelines for stripped edge matrix.

Lưu ý:

Measurements may vary ± 0.5 mm.

|

Paper* (cut sheet or dual web)

|

140–180 g/m

2

|

1.6 mm (0.0625 in.)

|

215.9 mm (8.5 in.) at leading edge

279.4 mm (11 in.) at driver edge (left margin side)

|

|

Vinyl

|

265–300 g/m

2

|

|

Polyester and other face materials

|

Varies

|

Using cut sheet labels with adhesive applied to the edge of the sheet contaminates and voids your printer and cartridge warranties.

When using pressure-sensitive materials without zone coating, choose butt cut labels without any stringers and with a stripped edge matrix. If a total strip matrix is in the design for the final product, then print before removing the matrix. If the matrix must be removed before printing, then round all corners, making sure that adhesive is not exposed.

Cut sheet paper labels

Generally, cut sheet paper labels work well with your printer.

Coating or sizing to make the paper liquid-resistant decreases toner adhesion and increases the risk of toner contaminating the fuser. At a minimum, paper labels should be equivalent in weight and rigidity to a 20-lb xerographic bond paper.

Dual web forms

Constructing dual web forms involves joining rolls of two different materials (usually pressure-sensitive paper and bond paper) and then converting to a cut sheet product. This construction requires a stripped edge matrix. The liner must be rigid enough to withstand the pick force of the printer. The two materials must be thin enough for the sheet to lie flat in the paper tray. The differences in thickness may cause the materials to curl down toward the leading edge of the form which can negatively affect feeding.

We recommend that the leading label edge should be thicker than the dual web overlap to make sure that the sheet lies flat in the tray. The label should be placed with the label facedown in the tray. Orient the label in the tray so that the pressure-sensitive area feeds into the printer first. The label should have no adhesive exposed in the overlay area or anywhere along the front or back of the label.

We recommend designing a non-adhesive strip with a minimum width of 1 mm (0.04 in.) along the edges of the overlay. To help prevent material from slipping in the fuser, we recommend knurling, which roughens up the exposed silicon area at the glue joint.

The face sheet of a dual web form is usually a paper pressure-sensitive product; therefore, the guidelines for paper labels are applicable to dual web forms.

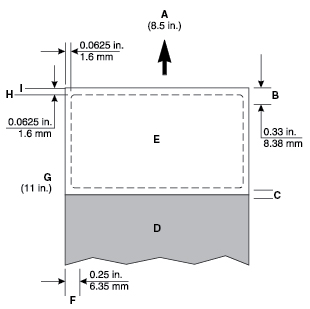

The following diagram shows the recommended dual web form design. The non-print area may vary depending on the printer model.

|

A

|

Leading edge

|

|

B

|

Non-print area

|

|

C

|

Overlay

|

|

D

|

Paper

|

|

E

|

Pressure-sensitive

|

|

F

|

Non-print area

|

|

G

|

Reference edge

|

|

H

|

Stripped edge

|

|

I

|

Liner edge

|

Vinyl and polyester labels

Vinyl labels work well within specified design parameters. Vinyls are heat-sensitive, so the liners need to be thick enough to absorb excess heat and prevent melting. A total strip matrix may cause adhesive contamination. Thin liners or weak pull strength may lead to labels peeling off the label inside the printer, which requires printer servicing.

Materials, which have liner face melt temperatures lower than the fuser temperature, may require the leading and trailing edge stripped areas to be 1.6 mm maximum due to feeding problems. We recommend that the liner face is constructed with material that can withstand the fuser temperature, which eliminates changing the stripped areas from 3 mm to 1.6 mm.

When a 1.6-mm stripped area is used, it is very important that the 1.6-mm tolerance be held tightly. With a stripped area of less than 1.6 mm, it is highly possible that adhesive contamination will occur.

Vinyls are non-absorbing, which leads to toner buildup in the fuser that requires special maintenance. For more information about maintaining your printer, see the documentation that came with your printer. Vinyls may require a topcoat to ensure good toner adhesion. When you run vinyl labels, you may be required to install an oil fuser cleaner.

Polyester labels are less heat-sensitive but are also non-absorbing. Backings for polyester labels can be thinner, but requirements for coatings and cleaning are similar to vinyl labels.

Integrated forms

To create integrated forms, the converter uses hot melt adhesives to apply the label adhesive and liner to a base material (generally paper).

Oil bleed, recognizable by a discolored face sheet, can be a problem with these forms. Oil may also migrate from the top to the back surface of the liner while it is on the roll, before the conversion process takes place. The forms may be slick, and the pick mechanism of your printer may be unable to move all the sheets from the tray into the printer. Jamming and misfeeds increase when oil is present on the back of the liner.

The adhesive on these forms is commonly patterned on two or four sides (a non-adhesive border on either two or four edges). We recommend designing a 1-mm (0.04-in.) non-adhesive border (zone coated) on all four edges.

When printing on integrated forms with a grain long base material, position the form in the tray so the paper portion of the form feeds into the printer first. Position the pressure-sensitive portion of the form toward the portrait left edge. For integrated forms with a grain short base material, position the form in the tray so the pressure-sensitive portion feeds into the printer first.

Due to the unique construction of integrated forms, you may experience stacking problems in the output bin. If you experience stacking problems with these forms, then contact your marketing representative.

Lưu ý:

Test some forms before purchasing large quantities.

In trên nhãn

Chỉ in trên các tờ nhãn đầy đủ. Các tờ bị thiếu nhãn có thể bong ra trong khi in và làm kẹt giấy. Một phần tờ giấy cũng có thể để lại vết dính trên máy in và hộp mực, điều này có thể làm mất hiệu lực bảo hành dịch vụ của máy in và hộp mực.

Không nạp nhãn qua máy in nhiều lần. Keo dính có thể làm bẩn hộp mực và các thành phần khác.

Tùy thuộc vào model máy in của bạn và số lượng nhãn được in, in nhãn có thể yêu cầu bảo trì máy in đặc biệt. Để biết thêm thông tin về cách in trên nhãn, vui lòng xem

Hỗ trợ giấy dành riêng cho máy in

.

Quy trình bảo trì

Lưu ý:

Quy trình này chỉ áp dụng cho máy in laser trắng đen.

Nếu chất lượng bản in bắt đầu giảm khi in trên nhãn vinyl, hãy làm như sau:

-

In trên năm tờ giấy.

-

Đợi khoảng năm giây.

-

In trên năm tờ giấy nữa.

Để duy trì độ tin cậy khi nạp giấy vào máy in, hãy lặp lại quy trình vệ sinh này mỗi khi bạn thay thế hộp mực in.

Lưu ý:

Việc bạn không tuân theo quy trình bảo trì cho máy in có thể gây kẹt giấy, chất lượng bản in kém, các sự cố nạp giấy và bộ sấy.

In nhãn hai mặt

Nhãn thường không được in hai mặt vì có cấu trúc đặc biệt. Tuy nhiên, có thể in trên cả hai mặt của tờ nhãn nếu tuân thủ một số nguyên tắc thiết kế, cấu tạo và sử dụng nhất định.

Khi phát triển nhãn giấy để in hai mặt, bên chuyển đổi phải đảm bảo nhãn được thiết kế để bảo vệ chống nhiễm bẩn hoặc tích tụ. Nhiễm bẩn dẫn đến các sự cố về nạp giấy và kẹt giấy.

Chúng tôi khuyên bạn nên sử dụng các tờ nhãn có đường viền không dính xung quanh khu vực nhãn. Đảm bảo độ bền bóc tách đủ để chịu được nhiệt độ 225°C (437°F) và áp suất lên đến 25 psi.

Sử dụng dây buộc nhãn khi cần thiết. Những vùng không cắt nhỏ này (xấp xỉ 1,6 mm hoặc 0,06 inch) giúp ổn định tờ nhãn và tránh bị rách ở các lỗ đục và khuôn cắt trong quá trình in. Dây buộc nhãn cũng ngăn không cho nhãn phân phối trước trong máy in.

Các khe và vết cắt trên nhãn làm lộ keo dính cho máy in. Để có kết quả tốt nhất, hãy định vị tờ nhãn sao cho các khe và vết cắt không thẳng hàng với các đường gân trong khu vực in hai mặt hoặc in lại của máy in. Làm như vậy sẽ loại bỏ bất kỳ điểm tiếp xúc nào giữa keo dính nhãn và máy in, ngăn bẩn keo dính trong máy in. Để biết thêm thông tin, vui lòng xem

Hướng dẫn thiết kế mẫu đường gân chính để căn chỉnh cạnh tham chiếu

.

Nạp các tờ nhãn có đầu nhãn trước. Sử dụng giấy thớ dài thay vì giấy thớ ngắn, loại giấy này thường dễ bị quăn.

Nếu bên chuyển đổi phát triển tờ nhãn thớ ngắn để in hai mặt, thì hãy kiểm tra tờ này trước để đảm bảo hoạt động bình thường.

Lưu ý:

Chúng tôi khuyến nghị thử nghiệm bất kỳ tài liệu nào với ứng dụng và máy in của bạn trước khi mua số lượng lớn.

Để sử dụng ứng dụng nhãn in hai mặt, bạn có thể phải lắp cần gạt bộ sấy. Cần gạt cho phép máy in in trên cả hai mặt của nhãn giấy. Để xác định xem máy in của bạn có cần gạt hay không, vui lòng xem

Hỗ trợ giấy dành riêng cho máy in

.

Hướng dẫn thiết kế mẫu đường gân chính để căn chỉnh cạnh tham chiếu

-

Chức năng của mẫu đường gân chính là hỗ trợ tốt nhất cho giấy trong quá trình vận chuyển. Nếu giấy chạm vào bề mặt nhất định, thì bề mặt đó phải có mẫu đường gân chính.

-

Đường nạp giấy phải hướng cạnh trước của giấy vào bề mặt dẫn hướng chính chứ không phải bề mặt phụ. Căn chỉnh này cung cấp vị trí xác định cho cạnh trước của giấy trên bề mặt dẫn hướng để hỗ trợ tốt nhất.

-

Góc tới cạnh trước của giấy khi chạm vào bề mặt dẫn hướng chính không được lớn hơn 30°. Góc này giúp loại bỏ giấy bị kẹt trên thanh dẫn và giảm năng lượng đầu vào của thanh dẫn.

-

Mẫu đường gân chính phải có giá đỡ đường gân kéo dài ra từ 3 đến 10 mm (0,12 và 0,40 inch) tính từ mép giấy. Đối với phong bì, giá đỡ đường gân phải kéo dài ra từ 2 đến 10 mm (0,08 và 0,40 inch) tính từ mép của phong bì. Giá đỡ đường gân này giữ cho các góc của giấy cứng để không bị gập lại và bắt các bề mặt khác trong máy in. Giá đỡ cũng ngăn các góc của giấy chạm vào bề mặt bên trong của đường gân giấy.

-

Mẫu đường gân chính không được có bất kỳ đường gân nào gần mép ngoài của giấy và phong bì quá 3 mm (0,12 inch). Dung sai đường gân này giữ cho giấy không chạm vào đường gân quá gần mép giấy.

-

Khoảng cách đường gân tối đa của mẫu đường gân chính không được lớn hơn 20 mm (0,79 inch). Khoảng cách giữ cho cạnh trước của giấy phẳng khi di chuyển qua hệ thống.

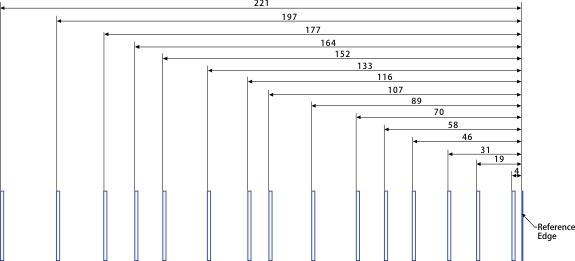

Mẫu đường gân cho Lexmark C6160, CS820, CS827, CX820, CX825, CX827, CX860, XC6152, XC8155, XC8160

|

|

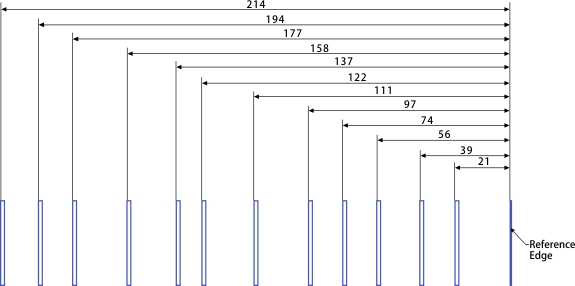

Mẫu đường gân cho Lexmark C4150, C4342, C4352, CS720, CS725, CS727, CS728, CS730, CS735, CX725, CX727, CX730, CX735, XC4140, XC4150, XC4342, XC4352

|

|

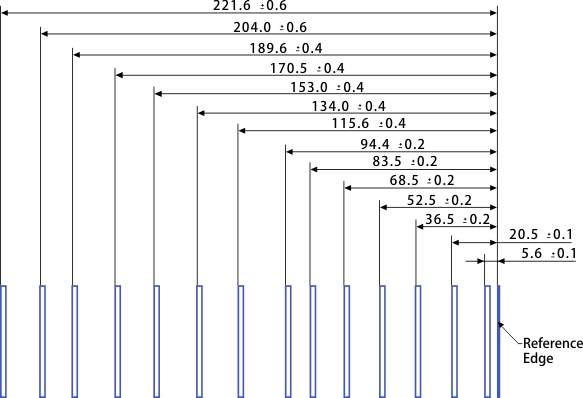

Mẫu đường gân cho Lexmark B2865, M5255, M5265, M5270, MB2770, MS725, MS821, MS822, MS823, MS824, MS825, MS826, MX721, MX722, MX725, MX822, MX824, MX826, XM5365, XM5370, XM7355, XM7365, XM7370

|

|