The following tables provide information on standard and optional paper sources and the sizes, types, and weights of paper that they support.

|

Paper size |

Standard 550-sheet tray, optional 250- or 550-sheet tray |

Optional 2100-sheet tray |

Multipurpose feeder |

Two-sided printing |

|---|---|---|---|---|

|

* A5 long edge feed (LEF) is recommended over A5 short edge feed (SEF). |

||||

|

A4 210 x 297 mm (8.3 x 11.7 in.) |

|

|

|

|

|

A5 LEF * 210 x 148 mm (8.3 x 5.8 in.) |

|

|

|

|

|

A5 SEF * 148 x 210 mm (5.8 x 8.3 in.) |

|

X |

|

X |

|

A6 105 x 148 mm (4.1 x 5.8 in.) |

|

X |

|

|

|

JIS B5 182 x 257 mm (7.2 x 10.1 in.) |

|

X |

|

|

|

Oficio (Mexico) 216 x 340 mm (8.5 x 13.4 in.) |

|

|

|

|

|

Statement 140 x 216 mm (5.5 x 8.5 in.) |

|

X |

|

|

|

Executive 184 x 267 mm (7.3 x 10.5 in.) |

|

X |

|

|

|

Letter 216 x 279 mm (8.5 x 11 in.) |

|

|

|

|

|

Legal 216 x 356 mm (8.5 x 14 in.) |

|

|

|

|

|

Folio 216 x 330 mm (8.5 x 13 in.) |

|

|

|

|

|

Universal 105 x 148 mm (4.1 x 5.8 in.) to 216 x 356 mm (8.5 x 14 in.) |

|

X |

|

|

|

Paper size |

Output expander or high-capacity output expander |

4-bin mailbox |

Staple finisher |

Staple, hole punch finisher |

|||

|---|---|---|---|---|---|---|---|

|

Stack |

Staple |

Stack |

Staple |

Hole punch |

|||

|

A4 210 x 297 mm (8.3 x 11.7 in.) |

|

|

|

|

|

|

|

|

A5 LEF 210 x 148 mm (8.3 x 5.8 in.) |

|

|

|

|

|

|

X |

|

A5 SEF 148 x 210 mm (5.8 x 8.3 in.) |

|

|

|

X |

|

X |

X |

|

A6 105 x 148 mm (4.1 x 5.8 in.) |

|

|

X |

X |

X |

X |

X |

|

JIS B5 182 x 257 mm (7.2 x 10.1 in.) |

|

|

|

X |

|

X |

X |

|

Oficio (Mexico) 216 x 340 mm (8.5 x 13.4 in.) |

|

|

|

|

|

|

|

|

Statement 140 x 216 mm (5.5 x 8.5 in.) |

|

|

X |

X |

X |

X |

X |

|

Executive 184 x 267 mm (7.3 x 10.5 in.) |

|

|

|

X |

|

X |

X |

|

Letter 216 x 279 mm (8.5 x 11 in.) |

|

|

|

|

|

|

|

|

Legal 216 x 356 mm (8.5 x 14 in.) |

|

|

|

|

|

|

X |

|

Folio 216 x 330 mm (8.5 x 13 in.) |

|

|

|

|

|

|

|

|

Universal 105 x 148 mm (4.1 x 5.8 in.) to 216 x 356 mm (8.5 x 14 in.) |

|

|

X |

X |

X |

X |

X |

|

Paper type |

Standard 550-sheet tray, optional 250- or 550-sheet tray |

Optional 2100-sheet tray |

Multipurpose feeder |

Two-sided printing |

|---|---|---|---|---|

|

* To prevent transparencies from sticking together, print up to 20 pages only. Print the succeeding pages after three minutes. |

||||

|

Plain paper |

|

|

|

|

|

Card stock |

|

X |

|

|

|

Transparency * |

|

X |

|

X |

|

Labels |

|

X |

|

X |

|

Vinyl Labels |

|

X |

|

X |

|

Bond |

|

|

|

|

|

Letterhead |

|

|

|

|

|

Preprinted |

|

|

|

|

|

Colored Paper |

|

X |

|

|

|

Light |

|

X |

|

|

|

Heavy |

|

X |

|

|

|

Rough/Cotton |

|

X |

|

|

|

Custom Type [x] |

|

X |

|

|

|

Paper type |

Output expander or high-capacity output expander |

4-bin mailbox |

Staple finisher |

Staple, hole punch finisher |

|||

|---|---|---|---|---|---|---|---|

|

Stack |

Staple |

Stack |

Staple |

Hole punch |

|||

|

Plain paper |

|

|

|

|

|

|

|

|

Card stock |

|

X |

X |

X |

X |

X |

X |

|

Transparencies |

|

X |

|

X |

|

X |

X |

|

Labels |

|

X |

X |

X |

X |

X |

X |

|

Vinyl Labels |

|

X |

X |

X |

X |

X |

X |

|

Bond |

|

|

|

|

|

|

|

|

Letterhead |

|

|

|

|

|

|

|

|

Preprinted |

|

|

|

|

|

|

|

|

Colored Paper |

|

X |

X |

X |

X |

X |

X |

|

Light |

|

X |

X |

X |

X |

X |

X |

|

Heavy |

|

X |

X |

X |

X |

X |

X |

|

Rough/Cotton |

|

X |

X |

X |

X |

X |

X |

|

Custom Type [x] |

|

X |

X |

X |

X |

X |

X |

|

Paper type and weight |

Standard 550-sheet tray, optional 250- or 550-sheet tray |

Optional 2100-sheet tray |

Multipurpose feeder |

Two-sided printing |

|---|---|---|---|---|

|

1 Grain short is preferred for paper over 176 g/m ² (47 lb). 2 Pressure-sensitive area must enter the printer first. 3 28-lb bond envelopes are limited to 25% cotton content. |

||||

Plain paper or Bond 1

|

|

|

|

|

Transparency

|

|

X |

|

X |

Integrated forms 2

|

|

X |

|

|

Integrated forms

|

|

X |

|

|

|

Paper type and weight |

Output expander or high-capacity output expander |

4-bin mailbox |

Staple finisher |

Staple, hole punch finisher |

|||

|---|---|---|---|---|---|---|---|

|

Stack |

Staple |

Stack |

Staple |

Hole punch |

|||

Plain paper or Bond

|

|

X |

|

X |

|

X |

X |

Plain paper or Bond

|

|

|

|

|

|

|

|

Card stock

|

|

X |

|

X |

|

X |

X |

Card stock

|

|

X |

|

X |

|

X |

X |

Card stock

|

|

X |

X |

X |

X |

X |

X |

Card stock

|

|

X |

|

X |

|

X |

X |

Transparency

|

|

X |

|

X |

|

X |

X |

Paper labels

|

|

X |

X |

X |

X |

X |

X |

Integrated forms

|

|

X |

X |

X |

X |

X |

X |

Integrated forms

|

|

X |

X |

X |

X |

X |

X |

The following media types are supported only in Lexmark MS725 and MX725 printer models.

Vinyl and polyester labels

Narrow media batch jobs

The following table lists the maximum weights supported by the trays and the multipurpose feeder.

|

Paper source |

Card stock 1 |

Labels |

|||||

|---|---|---|---|---|---|---|---|

|

Index Bristol |

Tag |

Cover |

Paper |

Dual-web paper |

Polyester |

Vinyl |

|

|

1 See Grain orientation for specific recommendations. 2 Due to label design characteristics, unacceptable feeding may be experienced from the multipurpose feeder. |

|||||||

|

Standard and optional 550-sheet trays |

199 g/m 2 (110 lb) |

203 g/m 2 (125 lb) |

176 g/m 2 (65 lb) |

180 g/m 2 |

180 g/m 2 |

220 g/m 2 |

300 g/m 2 |

|

Multipurpose feeder 2 |

199 g/m 2 (110 lb) |

203 g/m 2 (125 lb) |

176 g/m 2 (65 lb) |

180 g/m 2 |

180 g/m 2 |

220 g/m 2 |

260 g/m 2 |

|

* 150–250 Sheffield is optimal. Using media higher than 300 Sheffield could result in printing degradation. |

||

|

Labels |

Thickness |

0.102–0.305 mm (0.004–0.012 in.) |

|

Smoothness |

100–400 Sheffield* |

|

Labels are one of the most difficult print materials for laser printers. Use a special fuser cleaner for label applications to optimize feed reliability and prevent duplexing.

It is recommended that you install the fuser oil cleaner, P/N 40X8579, when you run labels. When you order a new cartridge, make sure that it includes the correct fuser wiper.

It is possible to duplex certain labels that have been specifically designed for this application. To duplex labels, consult the Lexmark converter lists to see which converters have successfully developed this type of label. You must install the wax wiper, P/N 40X8581. Cartridges designed for duplex label printing contain two wax wipers. Change the wax wiper at the halfway point of your normal cartridge usage to provide extra cleaning and optimize performance. Contact your supplies and label specialist for information on oil and wax vinyl label cartridges.

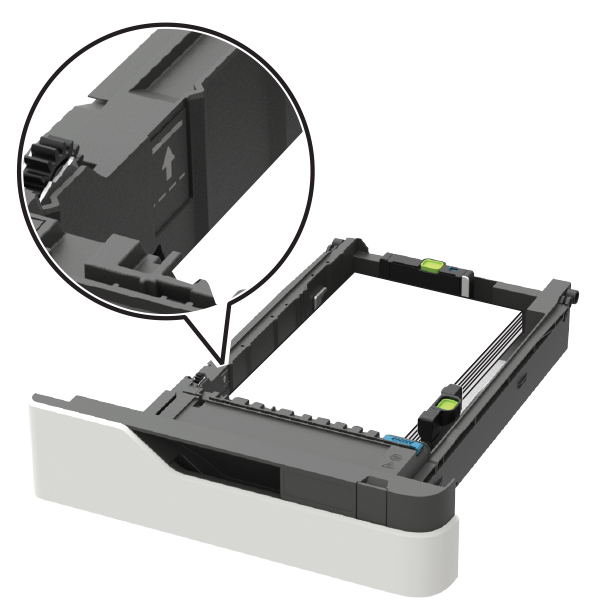

Depending on construction, labels and card stock can sometimes be difficult to pick and feed reliably. Performance can be improved by controlling the number of sheets of media loaded in the tray. There are two fill lines in the tray. The solid line is the maximum paper fill indicator. No media should be loaded in the tray above this line or paper jams could occur. The dashed line is the alternate paper fill indicator and should be used if any feed or reliability issues are noted with specialty media, including labels and card stock. If paper jams occur when completely filling the tray, load the specialty media only up to the alternate paper fill indicator.

For more information on the printer models and feeding different types of media, contact your Lexmark sales representative.

When printing on labels:

From the control panel, set the paper size, type, texture, and weight in the Paper menu to match the labels loaded in the tray.

Do not load labels together with paper or transparencies in the same tray. Combining print materials can cause feeding problems.

Use full label sheets. Partial sheets may cause labels to peel off during printing, resulting in a paper jam. Adhesive material may contaminate your printer. It could also void your printer and cartridge warranties.

During printing, the number of labels per sheet can affect registration more than basis weight. Typically, the more labels per sheet, the better the registration.

When printing on card stock:

From the control panel, set the paper size, type, texture, and weight in the Paper menu to match the card stock loaded in the tray.

Do not use card stock that is creased. It may cause paper jams.

For more information, see the following: